Grow a backbone

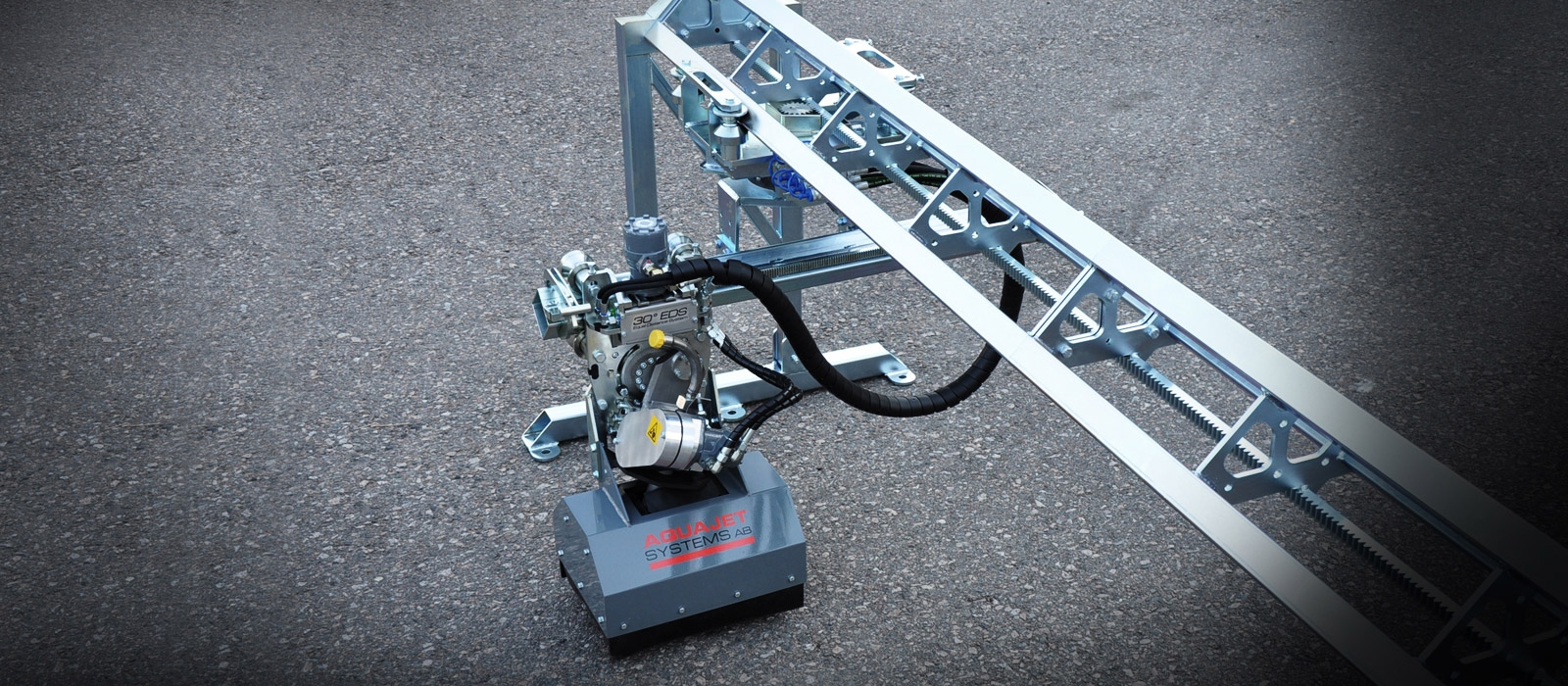

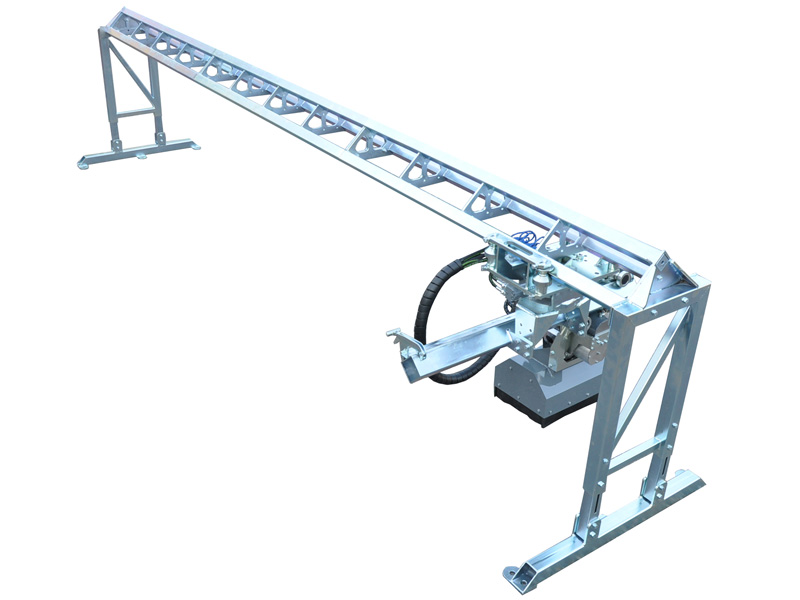

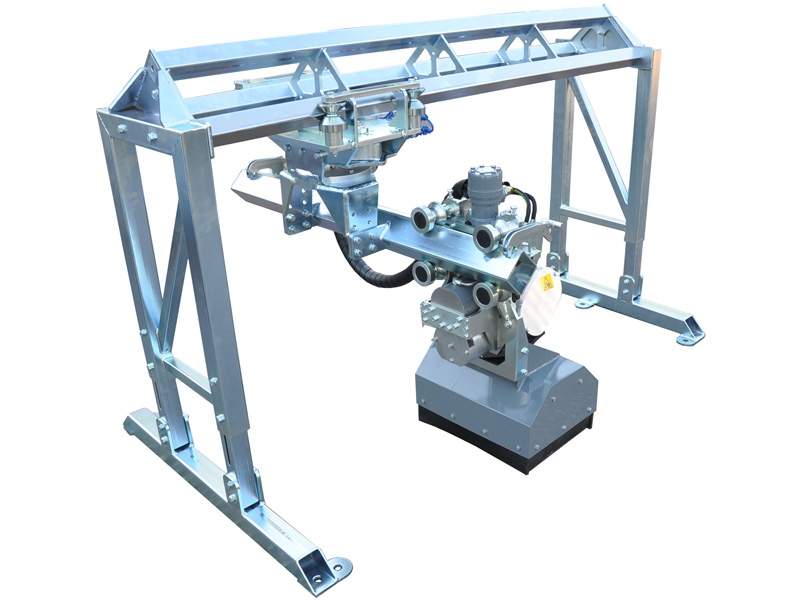

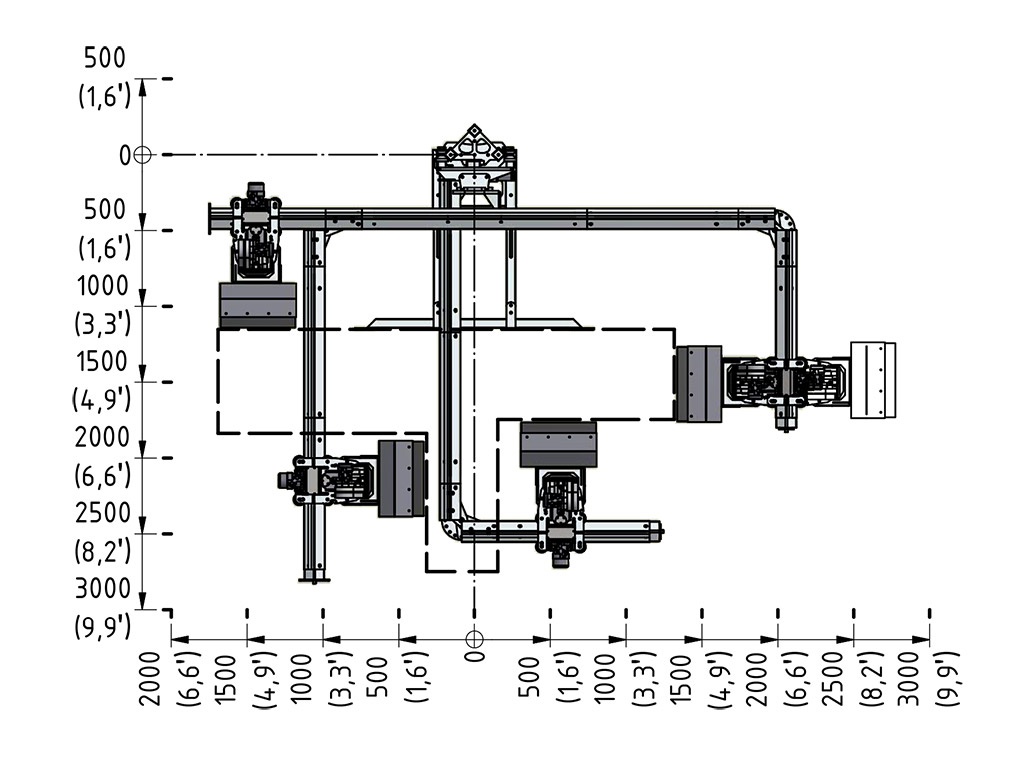

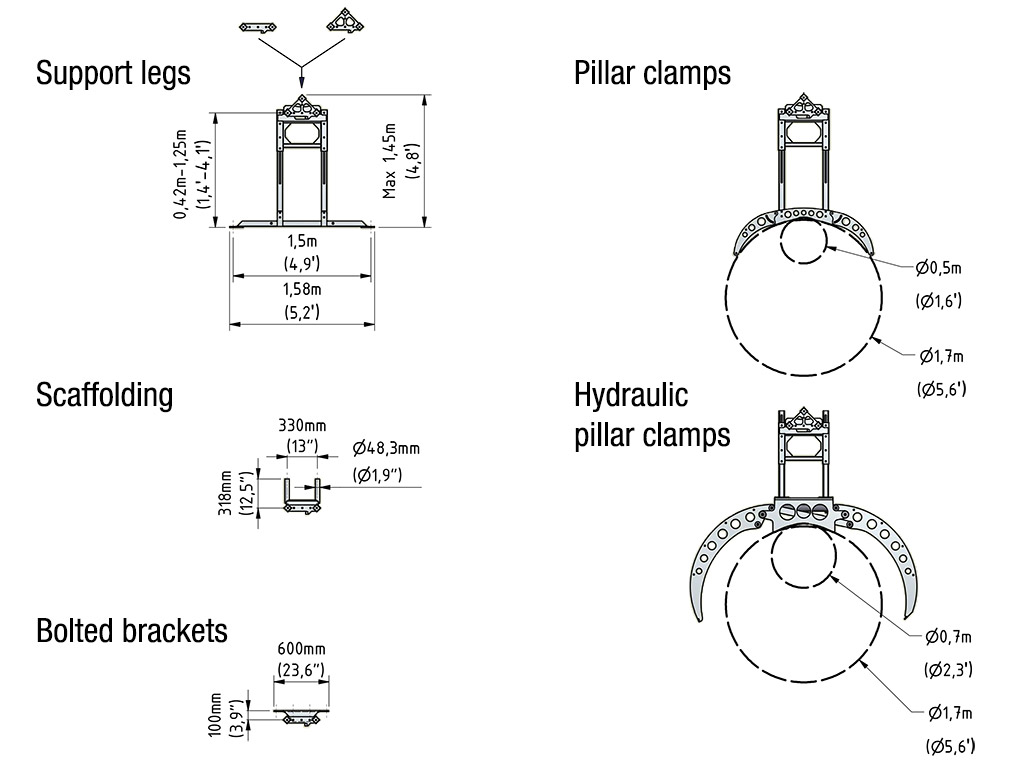

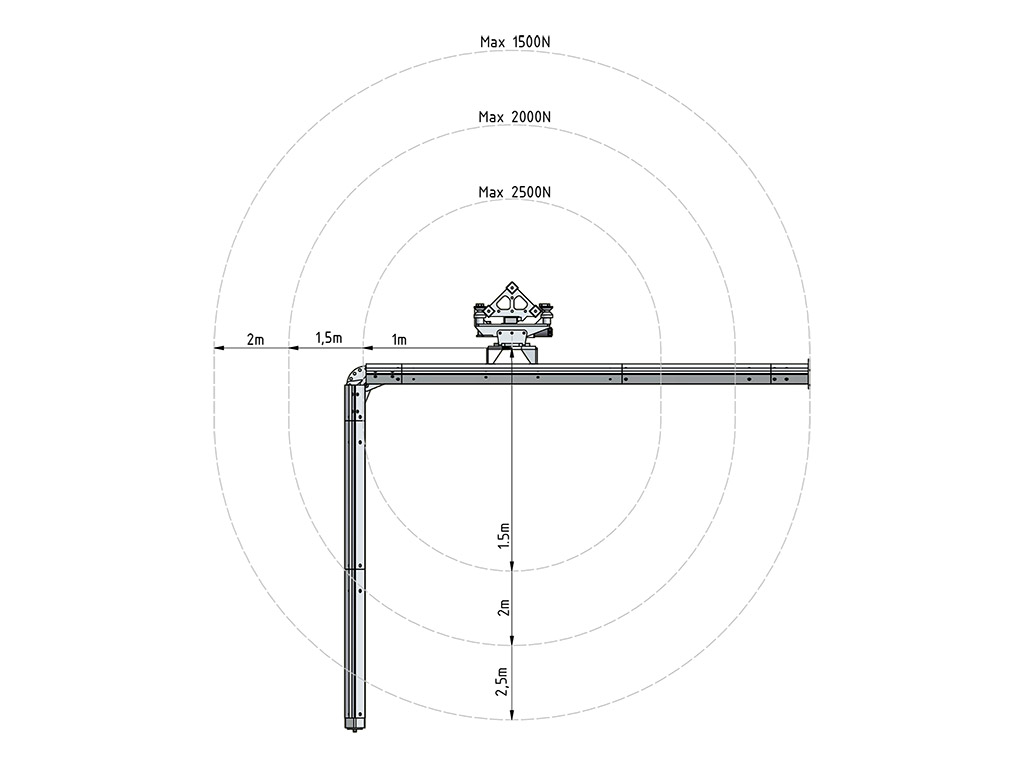

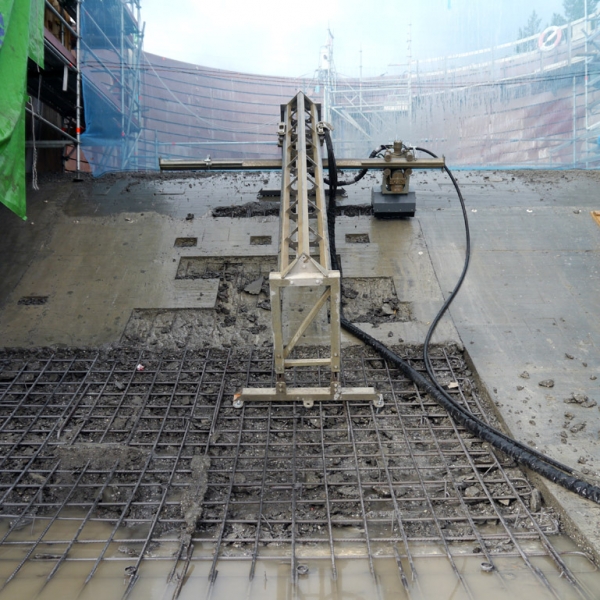

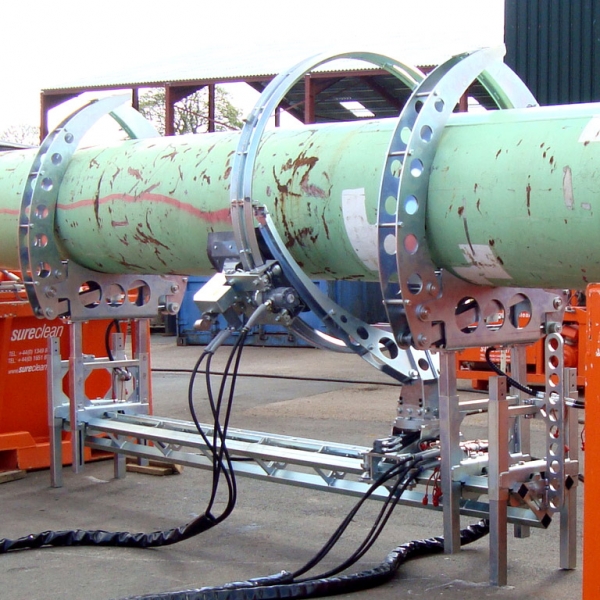

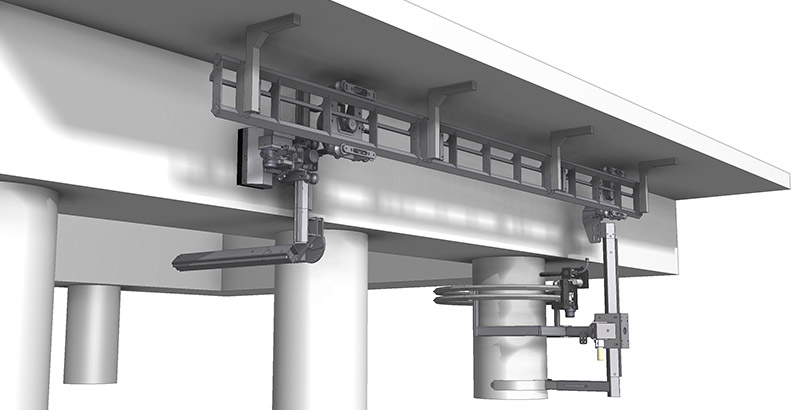

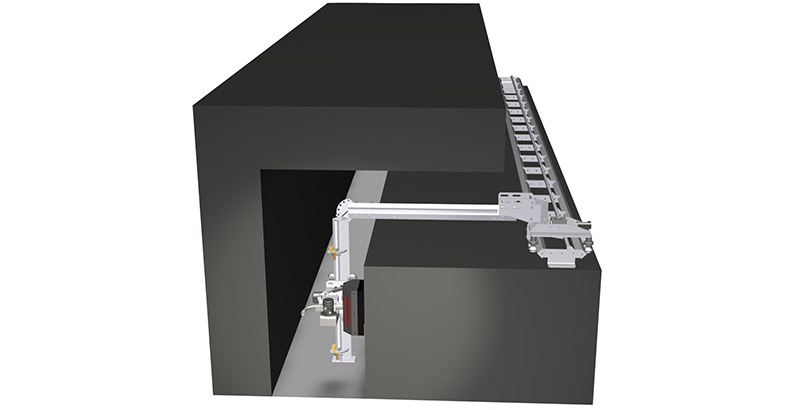

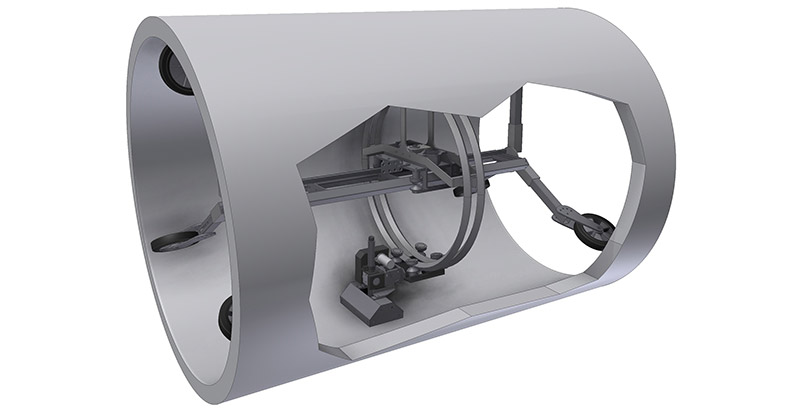

The system can be positioned directly on concrete by anchor bolts or supported by carriers such as hydraulic platforms, cranes and scaffoldings. It can be tailored, assembled and modified for specific tasks according to your own specifications. All power and control functions are provided by a standard Power Control Unit (PCU) or by any of our AQUA CUTTER robots.

Staying on track

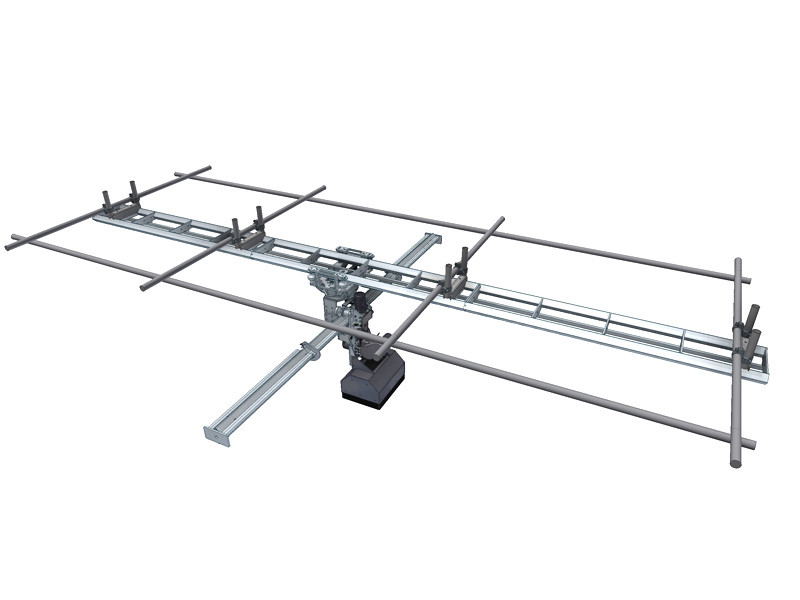

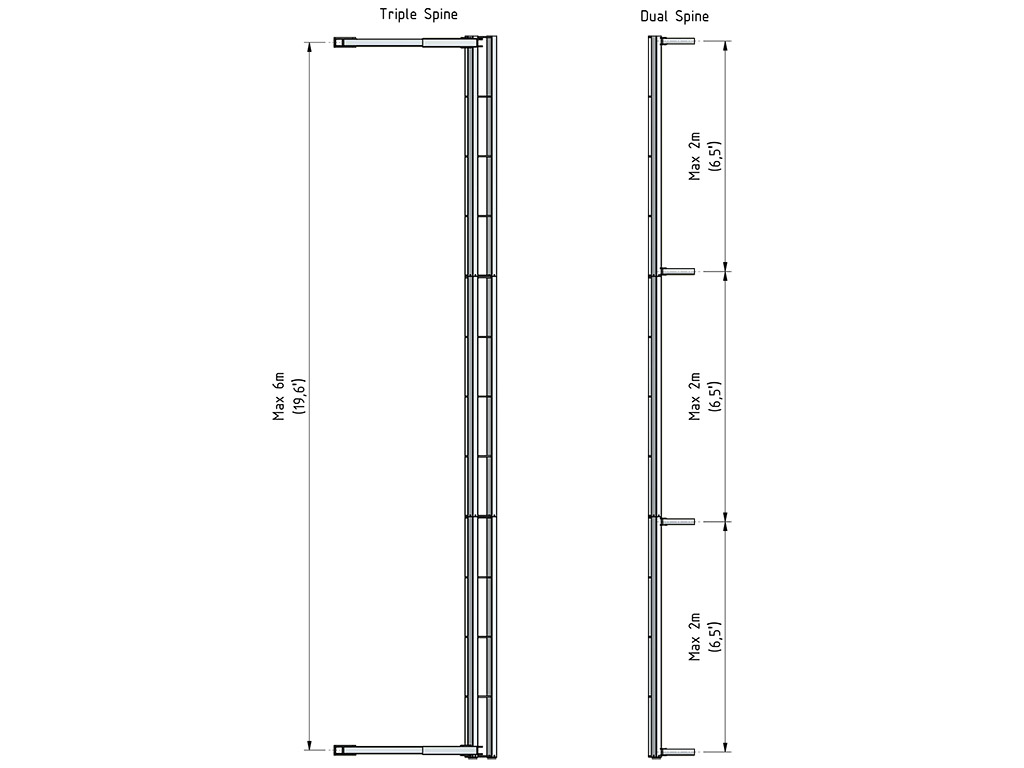

The AQUA SPINE has two different rail systems: DUAL or TRIPLE. Both are interchangeable within the system. You can use DUAL in confined areas or when you have several accessible attachment points to fix the rail. The TRIPLE rail is used for longer free span, up to 6 meters between the supports, horizontally or free standing.